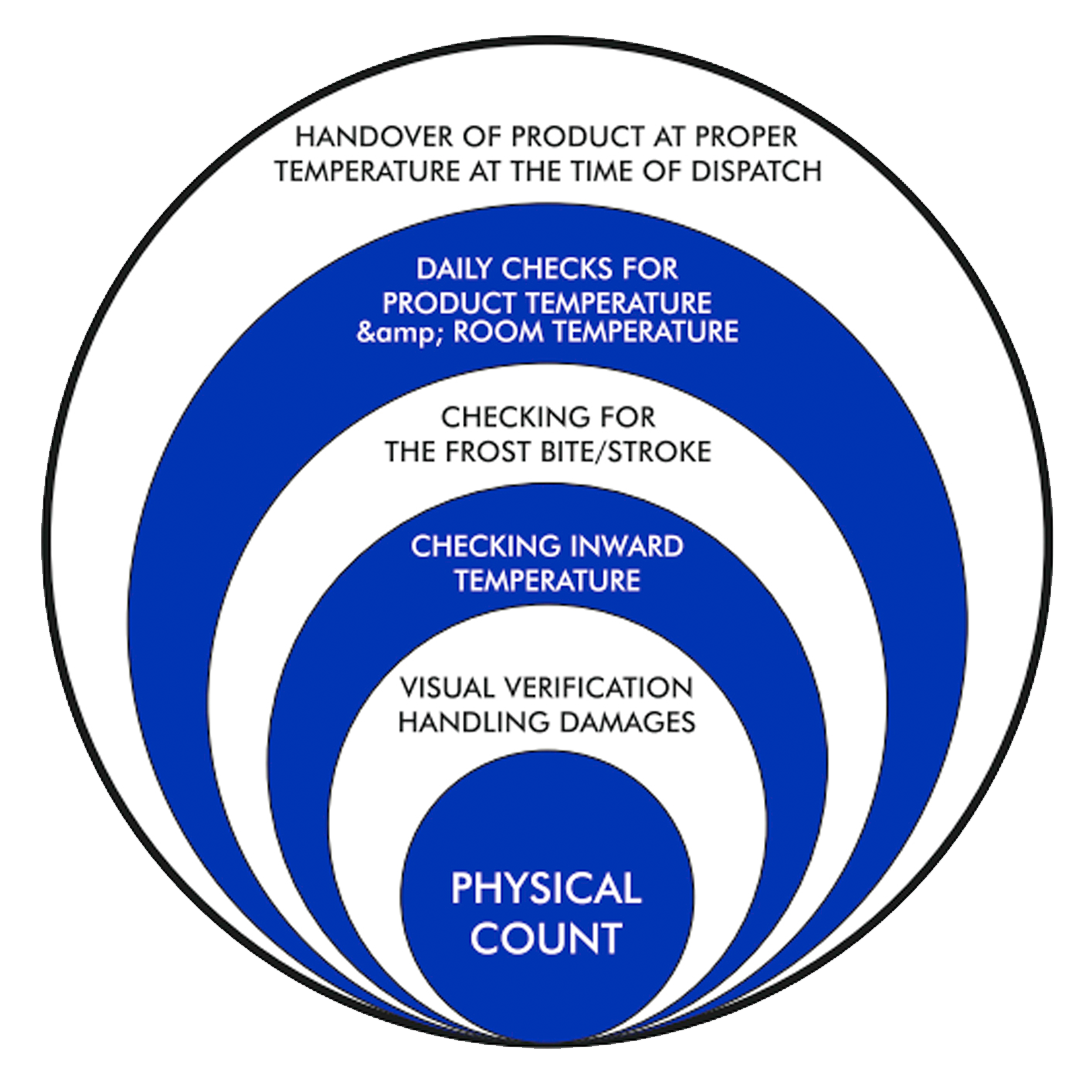

Checking Process

Physical Count

Physical counting of all items ensures that the quantities match the inventory records. This process helps in tracking discrepancies and maintaining accurate stock levels.

Visual Verification & Handling Damages

A thorough visual inspection is carried out to check for any visible damages or defects. Damaged products are identified, isolated, and documented for further handling.

Checking Inward Temperature

The temperature of incoming goods is measured to ensure they meet safety and quality standards. Accurate readings are critical for maintaining the freshness and integrity of perishable goods.

Checking for Frostbite/Stroke

Regular checks are performed to detect frostbite or temperature inconsistencies in stored products. Early detection helps prevent product degradation and ensures optimal storage conditions.

Daily Check for Product & Room Temperature

A daily routine involves monitoring both product and room temperatures to ensure compliance with safety regulations. These checks are essential to prevent spoilage and maintain the quality of stored goods.

Handover of Product at Proper Temperature During Dispatch

Before dispatching goods, a final check is made to ensure they are handed over at the proper temperature. This guarantees that the cold chain is maintained until the product reaches its destination.